AC110/AC127V/AC230V/260V 8mm/10mm/12mm/13mm/15mm/16mm 180LED/Mac High Voltage LED Flexible Strip for Construction Sites, Tunnel, Road Maintenance, Tree Lighting

Product Advantages Environmental friendly PVC material, sulfur-free Copper conducting wire,heat dissipation coefficient

Basic Info

| Model NO. | ATA-XX28-180 |

| Viewing Angle | 120 Degrees, 360 Degrees |

| Color | White, Warm White, Natural White, Red, Green, Blue |

| PCB Width | 8mm, 10mm, 12mm, 13mm, 15mm, 16mm, 20mm |

| LED Quantity Per Meter | 60LED, 180LED, 60LED, 72LED, 84LED, 96LED, 120LED, |

| Cuttable Unit | 0.2m, 0.5m, 1m |

| Working Voltage | AC110V, AC220V, AC230V, AC240V |

| CRI | Ra80 |

| Lumen | 24-26lm/LED |

| Meter Per Reel | 5m/Reel, 10m/Reel, 25m/Reel, 50m/Reel, 100m/Reel, |

| Waterproof Method | Silicone Pipe, PVC Pipe |

| IP Grade | IP65 |

| Applications | Construction Sites, Tunnel, Road Maintenance, Tree |

| Working Temperature | -20~+60 Celsius Degree |

| Warranty | 2 Years |

| Transport Package | K=K Carton |

| Specification | 13*7mm, 15*7mm, 17*7mm, 20*8mm |

| Trademark | ATA |

| Origin | Made in China |

| HS Code | 9405409000 |

| Production Capacity | 500, 000/Meters/Month |

Product Description

Product Advantages

Environmental friendly PVC material, sulfur-free

Copper conducting wire,heat dissipation coefficient high to 0.28~0.30W/MK

20cm/cuttable,50cm/cuttable,100cm/cuttable,wide application

High voltage design,easy wiring and installation

Flexible, Smooth and continuous lighting for various shape

Free driver, directly connect the mains AC110V/AC220V/AC230V/AC240V

No voltage drop, high efficiency, 100meters can keep same brightness

Cuttable and Linkable

IP65 waterproof

Certification: UL, TUV, GS, CB, SAA, LVD, EMC, FCC, CE, RoHS

Technical Parameters

| Product Name | High voltage LED Flexible Strip | |

| LED Light Source | 2835, 5050, 5630, 5730 SMD LED | |

| Viewing Angle | 120 degrees, 360 degrees | |

| Power | 5W, 6W, 7W, 8W, 9W, 11W, 12W | |

| Working Voltage | AC110V, AC220V, AC230V, AC240V | |

| Color | White, Warm white, Natural white, Red, Green, Blue, Yellow, Pink, RGB | |

| PCB Width | 8mm, 10mm, 12mm, 13mm, 15mm, 16mm, 20mm | |

| PCB Color | White | |

| LED Quantity per meter | 60led, 70led, 120led, 144led, 180led, 240led, 276led | |

| Cuttable Unit | 0.2M, 0.5M, 1M | |

| Product Size (mm) | 13*7mm, 15*7mm, 17*7mm, 20*8mm | |

| Waterproof Rate | IP65 | |

| Waterproof method | Silicone Pipe, PVC Pipe | |

| Working Temperature | -20~+60 celsius degree | |

| Packing | 5m/reel, 10m/reel, 25m/reel, 50m/reel, 100m/reel, 200m/reel | |

The SMD light ribbon itself and all its components may not be mechanically stressed. Assembly must not damage or destroy conducting paths on

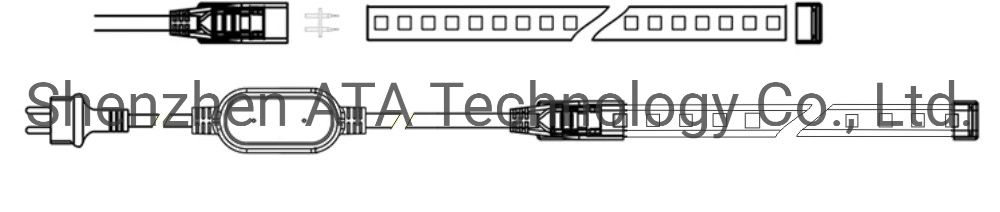

Each strip has plug and rectifier bridge pile, only need insert the plug into the power socket. Please specify the power of the product

before use to ensure that the power supply line is not overloaded and the circuit has circuit protector, If the power outlet with a fuse or

connected to the leakage switch, Please refer to the product technology and photoelectric parameters to ensure the operation within

the range of ±5% voltage parameters

If customized length is needed, it should be cut at the welding position of 0.5/1 meter unit group, not less than the minimum unit length

or cut within the unit group. After shearing, it should be noted that the incision should be sealed with waterproof insulating glue to avoid

burning the product or safety accidents (the product supplier is not responsible for the loss caused thereby). Our company does not

recommend customers to cut the length by themselves. If you need non-standard length products, please contact our marketing staff

Do not make continuous distortion of the lamp belt. Repeated distortion may easily cause fatigue damage to the internal power line.

The distortion angle shall not be less than 45 degrees, and don't bend below 60mm in diameter. Soft light belt in outdoor, indoor use

should do safety precautions, so as not to reduce fire, electric shock and personal injury

For the steady work of the product, please use the product in some places with good ventilation. It's forbidden to light the whole roll

of light strips together

Make sure life-span of led strip, we recommend not pulling power line hard during using, no impact and press surface of light source.

Fixing led strip must be solid, no losening and flying phenomenon, or it'll lead to breakage of cable and damage led strip

The end side of led strip must be sealed by end-cap, when use outdoor, connector must be solid, no hidden danger of short circuit.

Installed at outdoor, each connector must be sealed with glass glue or other sealing methods to seal seams, making sure each

connector waterproof

Install and fix, do not use iron wire metal maerial to tighten led strip to prevent iron wire drop into led strip, lead to short circuit and

electric leakage, burn led strip, etc.

Once discovering led strip worn, cut damaned unit at once, stop using any more to avoid danger

This prodcut is not kids toys, easy to arouse children's interest, pls install out of reach of children Or use under adult supervision.

Strictly forbidding using this product directly in some swimming pools, river,place where people are crwoded to prevent accidents

Applications

Indoor and outdoor decoration lightings.

Idea for in advertisement and cabaret, large scale backlight, cabinet, furniture, landscape outlines

Edge-lighting of transparent or diffused materials, to couple light into transparent or diffused glass

Bridge edge lighting

Window display lighting

Tree, garden lighting

Car and motorcycle decorative lighting

Path & Building contour decorative lighting

Emergency hallway lighting / rescue signs / advertising signs / light boxes

Architectural decorative lighting, villa, restaurant, hotel, meeting room, show room, shop, counter, etc

Festival lighting, General lighting, Task lighting, Household appliances, Architectural lighting, Decorative / pathway lighting, Street lighting

User Manual:

Switch off power of the mains supply or respectively of the connection lead before doing any works.

The complete installation must be done by an electrical expert who is familiar with the valid directives.

Quaity Control:

Stability TEST: make sure 100% of the lamps be aging test at least 48hours

Lighting TEST: make sure 100% of the lamps be lighted before packing

Drop TEST: make sure every single light have been well protected by box

Contact

Peony Jin

Mobile:0086-158 1858 6160

Please feel free to send us your inquiry, We are at your service any time!

Send to us